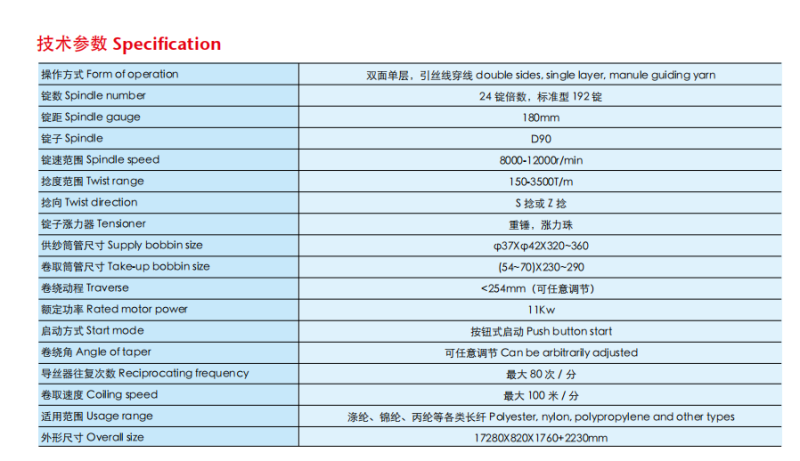

Factory wholesale Silk Yarn Twisting Machine - JX398B – GUOXING

Factory wholesale Silk Yarn Twisting Machine - JX398B – GUOXING Detail:

Performance characteristics:

It can be two-in-one, three-in-one, four-in-one, and can be adjusted freely according to customer requirements

Overfeeding adopts double-roller rollers to make the strands uniform

Servo-driven yarn guide traverses, using timing belt to reduce oil and ensure good quality

Precise positioning and reciprocating movement of the guide rod

It can be equipped with electronic thread detector to improve the quality and reduce the waste of raw yarn

Suitable for 30D~300D hemp, nylon, polypropylene and other long fibers, control the winding guide through the PLC control system and the servo drive device

The frame, capturing mechanism and various transmission mechanisms realize the main process parameters such as speed, twist and location on the touch screen.

It can be adjusted arbitrarily, and the styles of parallel, closed and loose edges can be set directly, which is convenient for change and meets the process requirements of different products

Features:

◇ It is possible to do two-in one, three-in one and four-in one by free adjustment according to customers’ requests.

◇ The double roller roller is applied for the overfeeding to achieve evenness and consistency of the plied yarns.

◇ The servo motor drives the yarn guide to move traversely.The synchronous belt is applied for transmission during the winding to reduce grease pollution so as to ensure a good positioning precision and a reciprocating movement for the yarn-guide rod.

◇ May mount electronic yarn detectors to elevate the yarn thread quality and reduce the raw yarn waste.

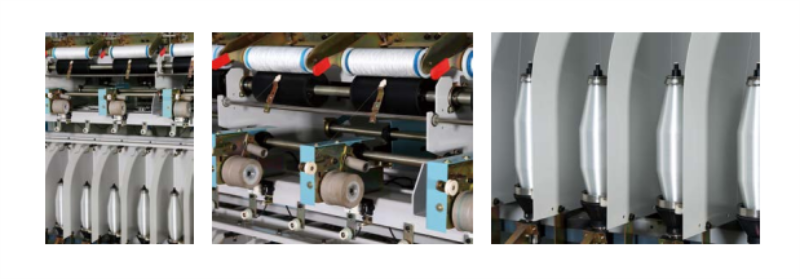

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Factory wholesale Silk Yarn Twisting Machine - JX398B – GUOXING , The product will supply to all over the world, such as: Albania, Porto, Qatar, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.