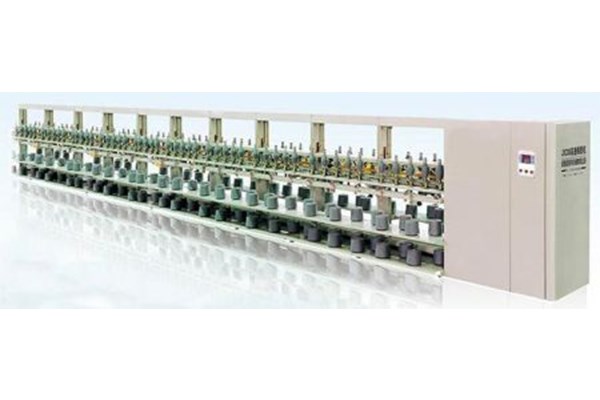

OEM/ODM Supplier Covering Machine For Metallic Yarn - GCM-2000D Elastic Thread Covering Machine – GUOXING

OEM/ODM Supplier Covering Machine For Metallic Yarn - GCM-2000D Elastic Thread Covering Machine – GUOXING Detail:

|

Model of equipment |

Unit of measurement |

GCM-2000D160 Spindle covering machine |

|

Norm of machine |

||

|

Seucture of machine |

Dual-face dual-layer |

|

|

Number of coiling layer |

Layer |

1 |

|

Number of wharve layer |

Layer |

2 |

|

Maximum coiling number of dual covering |

Position |

80 |

|

Number of node |

Node |

5 |

|

Number of ingot per node |

Position |

32 |

|

Out-form dimension(L×W×H) |

mm |

11000×1050×1800 |

|

Total weight of equipment |

kg |

3500 |

|

Spindle |

||

|

Number of spindle |

Spindle |

160 |

|

Type of spindles |

Fixed straight type/fixed conic type |

|

|

Distance between spindles |

mm |

200 |

|

Mechanical spindle speed |

rpm |

15000 |

|

Twisting direction of spindle |

S/Z |

|

|

Range of twisting degree |

Twist/m |

200-3500 |

|

Capacity of wrapped filament |

g |

550 |

|

Wrapped filament bobbin |

Φ84×Φ36×140 |

|

|

Coiling |

||

|

Out-form of coiling |

Double-cone integration |

|

|

Out-form dimension of coiling |

mm |

Φ180×140 |

|

Size of coiling tube |

mm |

Φ48×155/Cone-shaped paper tube |

|

MAximum coiling capacity |

g |

≤850 |

|

Coiling formation |

Mechanical formation/computerized formation |

|

|

Draftiong,electric and power |

||

|

Drafting range |

Multiple |

1.5-6 |

|

Power of the motor of the upper spindle |

kw |

5.5 |

|

Power of the motor of the lower spindle |

kw |

7.5 |

The lates GCM-2000D boot binder is for covering the rubber wire, latex wire by yarn in various specified single or dual layered wires and suitable for producing the weaved and elastic chiffon. The machine with frequency varied and speed regulating device is for adjusting the ingot’s rotation speed and saving up the electronic volume.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for OEM/ODM Supplier Covering Machine For Metallic Yarn - GCM-2000D Elastic Thread Covering Machine – GUOXING , The product will supply to all over the world, such as: Hanover, Algeria, Czech, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.